In stock

Woodshop Epoxy Penetrate

Woodshop Epoxy Penetrate

STABILIZES SOFT OR ROTTED WOOD FIBERS

Woodshop Epoxy Penetrate is a solvent-free, ultra-low viscosity epoxy system designed to deeply stabilize soft, damaged, or porous wood. Ideal for pre-sealing edges and surfaces before casting, laminating, or top-coating, it enhances adhesion, minimizes bubble release, and strengthens the substrate.

Penetrating deeply into raw, unfinished wood—especially when cut with up to 50% solvent (acetone or denatured alcohol)—Woodshop Epoxy Penetrate is perfect for preparing river tables, live-edge slabs, and outdoor restoration projects.

Apply the night before your pour and coat subsequent epoxy layers within 6-8 hours, while the surface is still slightly tacky, to achieve maximum chemical bonding. If fully cured, a light sanding is required for mechanical adhesion. Not for filling voids, lamination, or use over previously finished or stained wood.

Key Features

Key Features

Preparation

Preparation

Application

Application

Share this product

How It Works

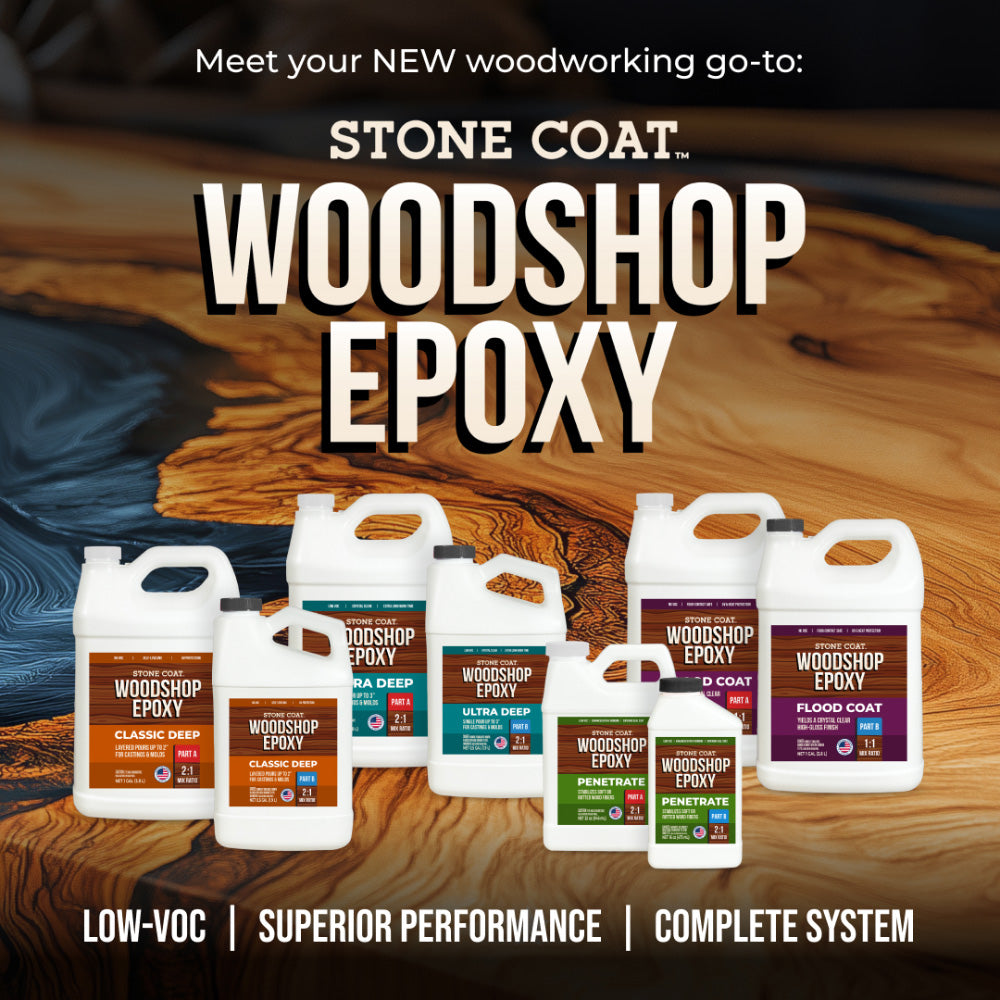

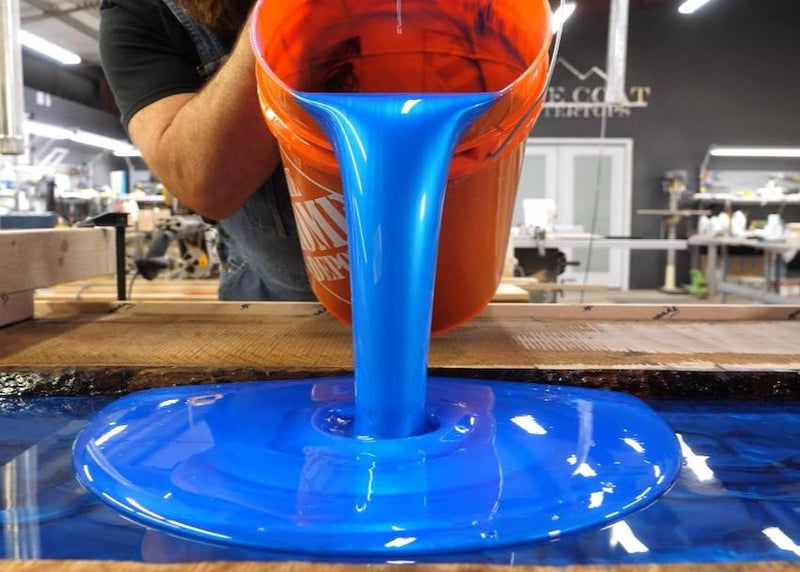

Start with our penetrating epoxy to set the perfect foundation, fill with your choice of deep pour epoxies, and finish with our crystal clear flood coat. The Woodshop Epoxy System is designed to work together, so you get consistent, professional results—without the guesswork.

Lock wood solid

Woodshop Epoxy Penetrate dives deep into the grain to stabilize fibers, seal out bubbles, and create a flawless foundation that bonds perfectly with your next pour.

Pour your way

From custom furniture to massive river tables, choose Woodshop Epoxy Classic Deep for pristine 2" layers or Woodshop Epoxy Ultra Deep for single 3" pours and up to 8" step pours. Long open times and low exotherm keep every project crystal clear.

Finish Strong

Our Woodshop Epoxy Flood Coat delivers a food-safe, crystal clear surface with maximum UV and heat resistance—built for lasting beauty and professional results.

Step-by-Step Guide

No trial and error, sanding hassles, or cross-brand issues—each product in the Woodshop Epoxy System is engineered to work together with smart curing windows for a smooth, uninterrupted workflow, giving you end-to-end compatibility from start to finish. Follow these simple steps to achieve perfect results.

Prep & Stabilize

Forget mismatched products and uncertain results—every great project starts with a stable foundation. Our Woodshop Epoxy Penetrate is designed to work seamlessly with the rest of the system, locking in wood fibers, sealing out bubbles, and ensuring your pour bonds perfectly.

How it works:

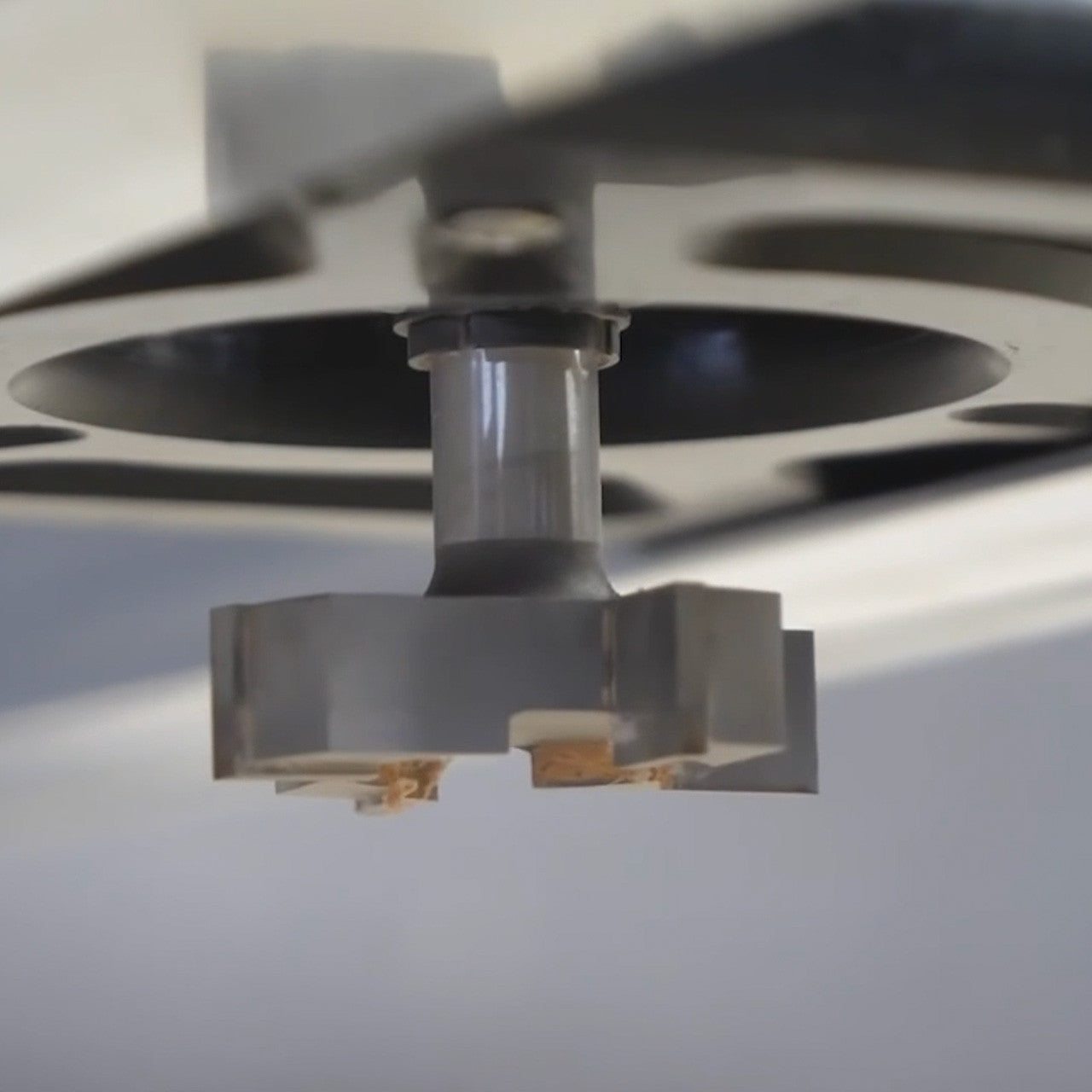

- Thin with up to 50% acetone or denatured alcohol for deep grain penetration (optional).

- Apply with a brush, syringe, or roller to raw wood and edges.

- Let sit for 4-8 hours until tacky for a strong chemical bond with your next epoxy layer.

- Prevents bubbles, edge delamination, and costly rework.

Pour Deep

Whether you’re crafting a small heirloom piece or a massive river table, our deep pouring epoxies are engineered for optical clarity, easy pours, and perfect compatibility with your prep and finish layers. No cure-window guessing, no cross-brand failures—just flawless results every time.

- For large molds and single pours up to 3".

- Ideal for step-pouring up to 8" total; re-pour at gel stage.

- Long open time and low exotherm for extreme clarity.

- Boost performance in warm environments with cool airflow under molds.

- For controlled 2″ layered pours.

- Re-pour at 4-6 hours when tacky to maintain chemical bond.

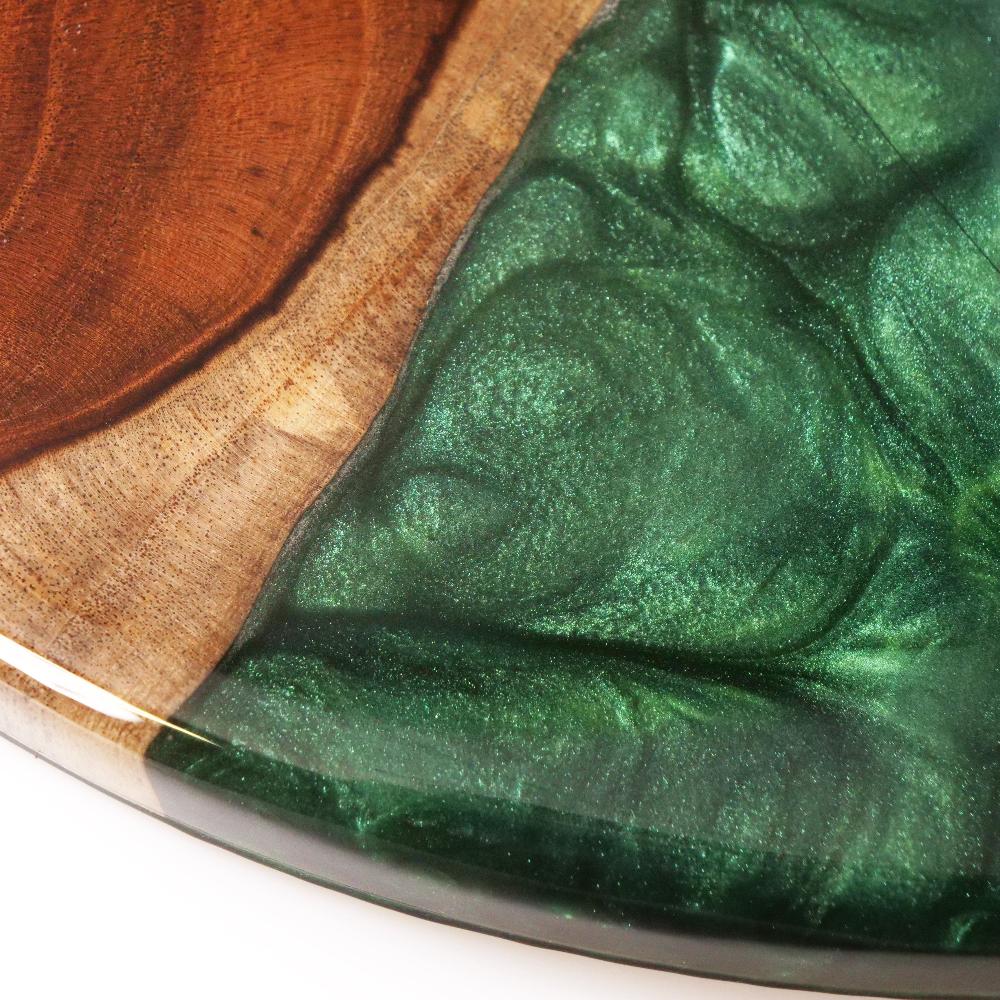

Both formulas are fully compatible with Polycolor Liquid Epoxy Dyes and PolyColor Metallic Pigment Powder for endless creative options.

Finish with Confidence

Seal in your craftsmanship with a finish built to last. Our Woodshop Epoxy Flood Coat delivers a crystal-clear, food-safe, UV- and heat-resistant surface that’s just as durable as it is beautiful. It’s the final step in a system designed to work together from start to finish—clear, consistent, complete.

How it works:

- Mix 1:1 and apply at ~3 oz per sq ft.

- Spread with a trowel or spreader, then brush or tip off.

- Remove surface bubbles with a torch or heat gun in a sweeping motion.

- Re-coat after 14-24 hours, or sand lightly if fully cured.

- Full cure in 7 days depending on ambient conditions.

Frequently asked questions

How much Woodshop Epoxy can I mix at once?

How much Woodshop Epoxy can I mix at once?

Do not mix more than one gallon at a time. For larger projects, pour in multiple steps. Only mix what you plan to use right away. Mixing too much at once can cause the Deep Pour epoxy to heat up too much while curing. This can lead to yellowing, warping, or cracking.

What is the best temperature for using the Woodshop Epoxy System?

What is the best temperature for using the Woodshop Epoxy System?

For the best results, keep your workspace and materials between 60°F and 80°F. Epoxy is sensitive to temperature:

- Cooler than 60°F: Epoxy gets thicker, traps air bubbles, and takes longer to level and cure.

- Warmer than 80°F: Epoxy becomes thinner and sets faster. It can get too hot, which may cause an exothermic reaction, yellowing, distortion, or cracking.

Try to work in a stable environment and avoid extreme temperature changes for the smoothest finish.

Do I need to wear protective gear?

Do I need to wear protective gear?

Woodshop Epoxy is Low-VOC, so it’s low odor and you don’t need a respirator mask. However, we recommend gloves and clothing that covers your skin to prevent contact with epoxy.

How do I clean epoxy from my tools?

How do I clean epoxy from my tools?

Use 91% isopropyl alcohol or Amazing Resin Remover to clean brushes, spreaders, trowels, or other tools. Remove epoxy right away, before it cures, for the easiest, hassle-free cleanup.

Does Woodshop Epoxy have a shelf life?

Does Woodshop Epoxy have a shelf life?

Yes! Woodshop Epoxy lasts about 12 months in sealed containers. For best results:

- Store between 60-90°F in a dry indoor place.

- Keep containers off the floor and away from outside walls.

- Do not freeze epoxy resins or hardeners.

- Reseal containers tightly after each use

Older or improperly stored epoxy can crystallize or yellow. If in doubt, mix a small test batch in a disposable cup to make sure it cures properly before starting your project.